MRD has been engaging with Universal Coal since mid-2011 to establish the feasibility of mining the coal reserve at the Kangala Mine Project, about five kilometres outside Delmas. The initial engagement resulted in a proposal for a full ”fit for purpose” model that suited the client’s requirements. Following Universal Coal’s securing all the necessary approvals, permits and a coal sales agreement with Eskom, the contract was negotiated with MRD. The contract covers the design, construction, commissioning and maintenance of a DMS Washing, Crushing and Screening plant.

The site is located approximately 65 kilometres east of Johannesburg, in the Witbank coalfield in the Mpumalanga province, which supplies more than 50 per cent of South Africa’s saleable export and domestic coal. Work commenced in the first week of April 2013 and first coal from the Crushing and Screening plant was produced in January 2014. The DMS plant was fully commissioned by 31 July 2014.

Universal Coal needed to optimise the processing plant in order to minimise the capital requirement for the development of the Kangala Coal Mine. A solution was presented to the client whereby the processing plant design was optimised with the intent to enter into a contract for the detail design, fabricate, construction, commissioning, operation and maintenance of the processing plant

By June 2012 MRD’s design team, together with specialist consultants completed the optimisation of the processing plant. Contract negotiations started in November 2012 and the contract was signed in April 2013. A major advantage of the solution provided was that detailed design and fabrication could start immediately off-site and on-site construction could start as soon as terracing was completed resulting in a fast-tracked programme and early production. The plant build was completed on time and within budget.

For the implementation phase of the project, the client adopted MRD’s high quality and safety standards. A quality management system, onsite safety procedures and various codes of practice were developed for the project with the client.

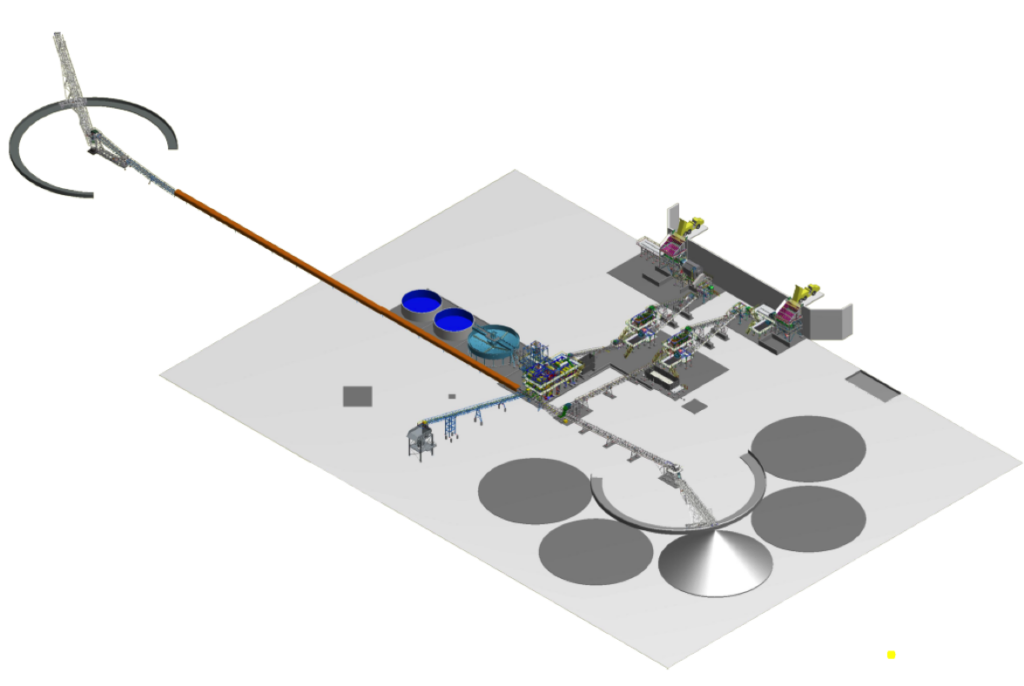

The processing plant was developed as a dual circuit processing facility consisting of a 350tph crushing and screening circuit plus a 320tph DMS washing plant. Each circuit can be operated individually or simultaneously.